Anhui Zhenzhou Machine Blade & Tools Manufacture

bar cutting blades

Basic Info.

Model NO.:1632

Blade Material:Stainless Steel

Handle Material:Plastic

Usage:Kitchen Knife

Folding:Unfolded

Product Description

Specifications

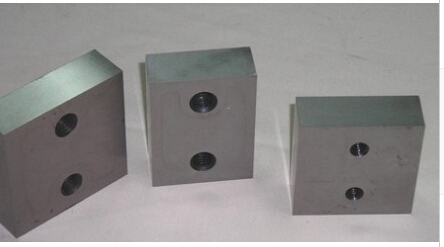

Bar cutting blade

Super high wear-resistance/high impact-resistance

Bar cutting blade

(Super high wear-resistance /high impact-resistance/high precision)

We can produce super long-wide-thick, high precision, complex profiling products according to requirements of

Drawings & samples.

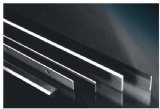

Length L=5mm~6500mm series, Width B=2mm~800mm series, Thickness T=0.10mm~120mm series,

Flatness can be

1. Machined work piece's minimum thickness is up to T= 0.20~0.06mm(and its maximum thickness is up to more than 800mm)

2. Machined work pieces' minimum diameter is up to φ D=φ 0.006 ( and its maximum diameter is up to more thanφ 600mm. )

3. Machined work pieces' maximum length is up to 6500mm (there is no limit for minimum length)

4. Flatness, parallelism, precision tolerance can be up to 0.005mm ~0.002mm~0.001mm high.

5. Machined work piece's thickness tolerance is up to T± 0.002mm~± 0.001mm~± 0.0005mm.

6. Surface roughness can be up to 0.2μ M~0.1μ M~0.05μ M~0.01μ M high.

HRF10:

Ultra micro-grain quality carbide, has excellent wear resistance, but its impact resistance is not so good. It is applicable for medium and low speed cutting of high hardness materials(HRC45° -65° ) requiring thermal refining and quenching or for various materials having higher wear resistance and non-ferrous metal. Generally it is applied in good working condition\stable cutting\excellent part fixing and continuous light machining. Corresponding to ISO K10.

PR40:

Ultra micro-grain diamond tungsten steel, extensively applied, it can be applied in medium speed cutting and finish cutting of various materials with HRC≤ 28° . It has excellent impact resistance and general wear resistance, and has extensive application. Generally, it is applied for thicker cutting, discontinuous cutting and bad part fixture. After being coated, it has better result, can machine various materials of HRC50° . Comparing with ISOK20≥neral tungsten steel, it has 1-2 times lifetime and excellent wear resistance

Bar cutting blade

Super high wear-resistance/high impact-resistance

Bar cutting blade

(Super high wear-resistance /high impact-resistance/high precision)

We can produce super long-wide-thick, high precision, complex profiling products according to requirements of

Drawings & samples.

Length L=5mm~6500mm series, Width B=2mm~800mm series, Thickness T=0.10mm~120mm series,

Flatness can be

1. Machined work piece's minimum thickness is up to T= 0.20~0.06mm(and its maximum thickness is up to more than 800mm)

2. Machined work pieces' minimum diameter is up to φ D=φ 0.006 ( and its maximum diameter is up to more thanφ 600mm. )

3. Machined work pieces' maximum length is up to 6500mm (there is no limit for minimum length)

4. Flatness, parallelism, precision tolerance can be up to 0.005mm ~0.002mm~0.001mm high.

5. Machined work piece's thickness tolerance is up to T± 0.002mm~± 0.001mm~± 0.0005mm.

6. Surface roughness can be up to 0.2μ M~0.1μ M~0.05μ M~0.01μ M high.

HRF10:

Ultra micro-grain quality carbide, has excellent wear resistance, but its impact resistance is not so good. It is applicable for medium and low speed cutting of high hardness materials(HRC45° -65° ) requiring thermal refining and quenching or for various materials having higher wear resistance and non-ferrous metal. Generally it is applied in good working condition\stable cutting\excellent part fixing and continuous light machining. Corresponding to ISO K10.

PR40:

Ultra micro-grain diamond tungsten steel, extensively applied, it can be applied in medium speed cutting and finish cutting of various materials with HRC≤ 28° . It has excellent impact resistance and general wear resistance, and has extensive application. Generally, it is applied for thicker cutting, discontinuous cutting and bad part fixture. After being coated, it has better result, can machine various materials of HRC50° . Comparing with ISOK20≥neral tungsten steel, it has 1-2 times lifetime and excellent wear resistance

Send Inquiry :

Related Products :

Products Category

Hot Products

-

recycling blades for ngr plastics and pelletizer knives hss material

recycling blades for ngr plastics and pelletizer knives hss material

ZZB-114 -

pelletizer blades plastic pelletizer knives crusher blade

pelletizer blades plastic pelletizer knives crusher blade

ZZB-109 -

granulator knives germany neue herbold granulator blades new granulator blade& pelletizer knives (8995)

granulator knives germany neue herbold granulator blades new granulator blade& pelletizer knives (8995)

ZZB-195 -

Self-Cleaning Flat Fan Spray Nozzle

Self-Cleaning Flat Fan Spray Nozzle

ZZB-2 -

shearing machine blades shear knife shear blade sheet metal shear machine blade

shearing machine blades shear knife shear blade sheet metal shear machine blade

ZZB-271 -

metallurgical industry bladeroller shear knife (8252)

metallurgical industry bladeroller shear knife (8252)

ZZB-125

Contact Us

Name: Phoebe

Tel: 0555-6061895

Fax: 0555-6061895

Mobile: +86-13721080868

E-mail: phoebe@zhenzhoublade.com

Add: Bowang New District, Maanshan City, Anhui Province, China

Whatsapp: +86 13721080868

Skype: phoebe_612

QQ: 43965370